In today’s competitive manufacturing landscape, every second counts. To stay ahead of the curve, businesses need to find innovative ways to increase efficiency and boost production output. One powerful tool that can help achieve this is the CNC rotary table, also known as a 4th axis table.

What is a CNC Rotary Table?

A CNC Rotary table is a precision-engineered attachment that mounts onto a Vertical Machining Center (VMC). It allows you to rotate the workpiece around a single axis, providing access to all sides for machining. This significantly expands the capabilities of your VMC, enabling you to create complex parts with greater accuracy and speed.

Benefits of Using Rotary Tables:

- Increased Speed: By eliminating the need to manually reposition the workpiece, rotary tables significantly reduce cycle times. This translates to more parts produced in less time, boosting your overall production output.

- Improved Accuracy: Precise rotation and indexing ensure consistent positioning of the workpiece throughout the machining process. This leads to superior product quality and fewer defects, reducing rework and waste.

- Reduced Setup Time: With a rotary table, you can perform multiple operations on a single setup. This eliminates the need to constantly remove and re-clamp the workpiece, saving valuable setup time and increasing machine uptime.

- Greater Versatility: Rotary tables open up a world of possibilities for machining complex geometries. They enable you to create parts with intricate features that would be difficult or impossible to achieve on a traditional VMC.

- Enhanced Ergonomics: By automating repetitive tasks and eliminating the need for manual indexing, rotary tables contribute to a better working environment for operators, reducing fatigue and potential injuries.

Kuvam Technologies: Your Partner in Production Boosting:

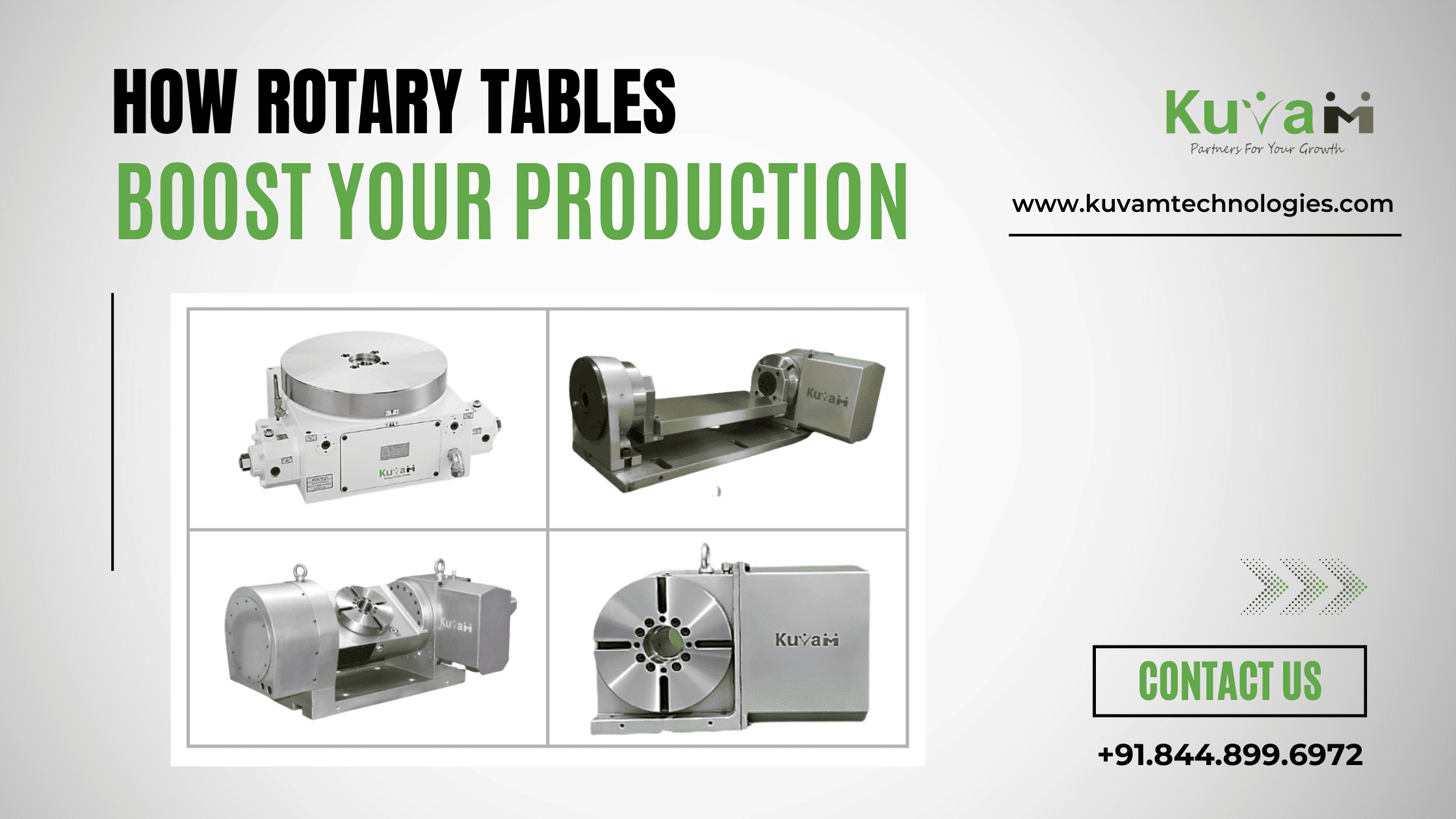

Kuvam Technologies is a leading manufacturer of high-quality CNC rotary tables designed to optimize your production process. They offer a wide range of models to meet your specific needs, including:

- Rotary production assembly tables: Streamline your assembly process with multiple workstations operating simultaneously.

- Tilting rotary tables: Access challenging angles and intricate geometries for precise machining.

- Hydraulic indexing tables: Achieve high speed, exceptional accuracy, and consistent repeatability.

Download our Catalog Now

Real-World Success Stories:

Businesses across diverse industries have experienced significant benefits by implementing Kuvam Technologies’ rotary tables:

- A leading automotive parts manufacturer increased their production output by 73% by using a Kuvam Technologies rotary production assembly table.

- Our client achieved a 47% reduction in cycle time for machining complex components with a Kuvam Technologies tilting rotary table.

- A leading faucet manufacturing company improved the accuracy of their products and reduced defect rates by using a Kuvam Technologies hydraulic indexing table.

Expert Advice for Choosing the Right Rotary Table:

Selecting the right rotary table is crucial for maximizing its benefits. Kuvam Technologies’ engineers recommend considering these factors:

- Size and capacity: Ensure the table can accommodate the size and weight of your workpieces.

- Accuracy and indexing resolution: Choose the level of precision required for your specific machining tasks.

- Indexing speed: Consider the speed requirements and cutting forces involved in your operations.

- Automation compatibility: Choose a table that seamlessly integrates with your existing automation systems.

Getting Started with Your Rotary Table:

To ensure optimal performance, follow these steps:

- Install and level the table properly.

- Mount the workpiece securely using the appropriate chuck or fixture.

- Program your VMC with the correct rotary table parameters.

- Start with slow speeds and gradually increase as needed.

- Monitor performance and adjust settings as necessary.